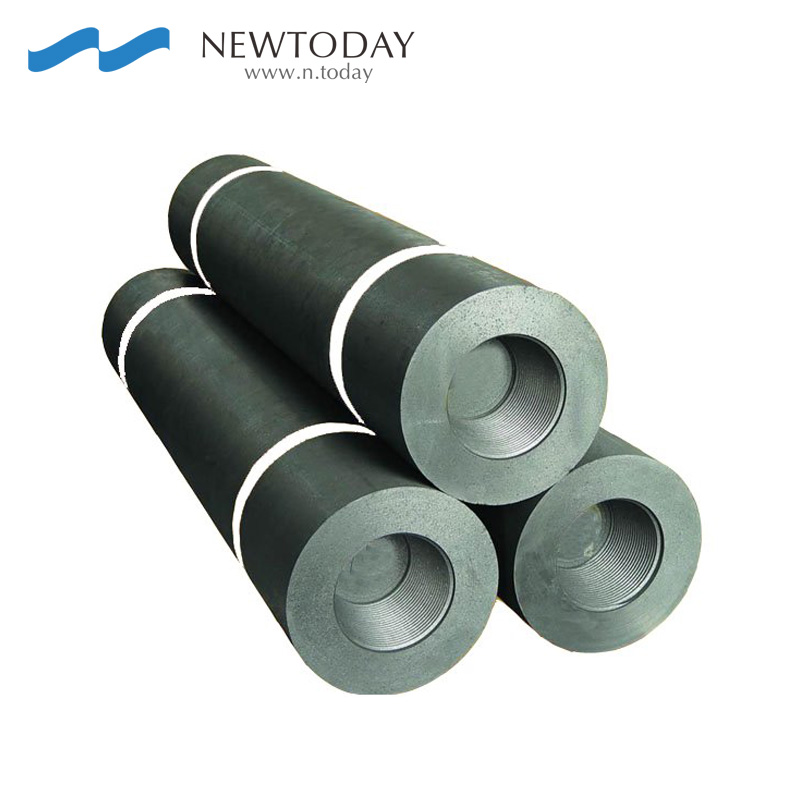

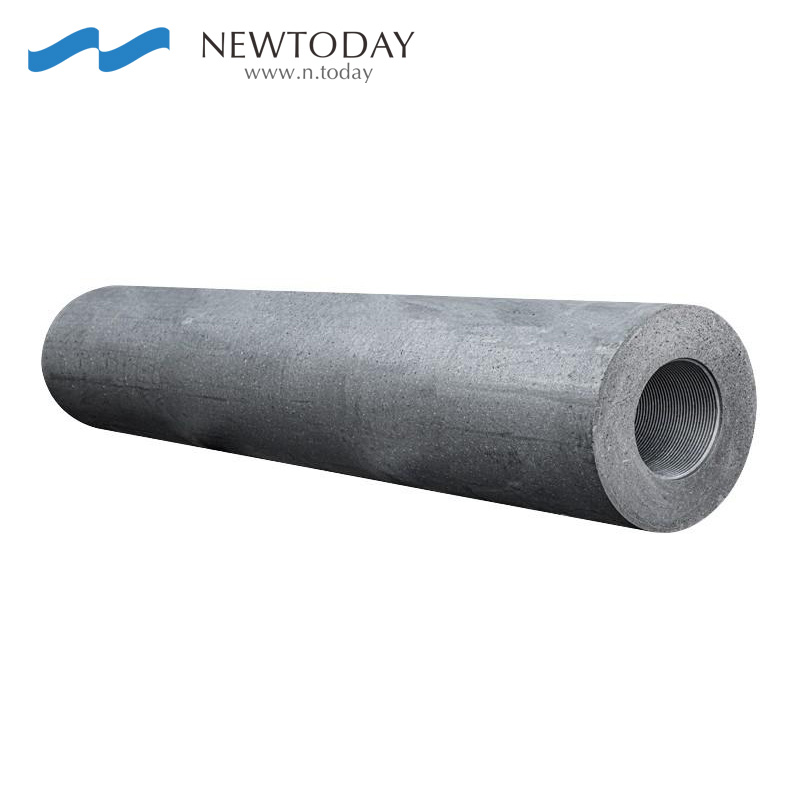

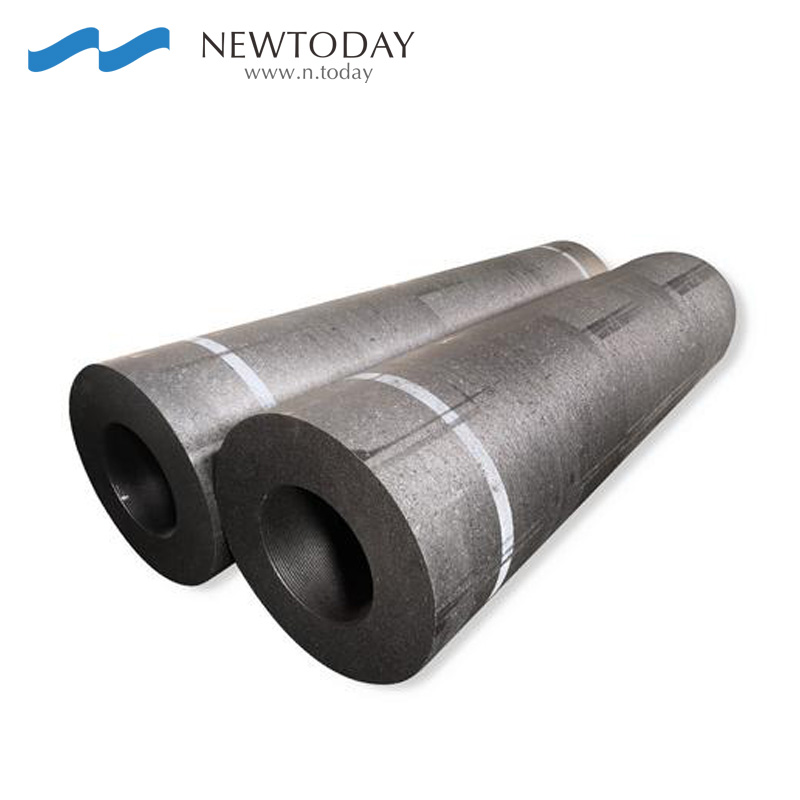

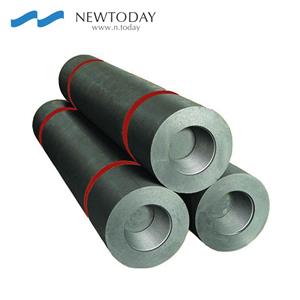

4tpi nipple graphite electrode and nipple uhp 450

- NEWTODAY

- CHINA

- 7-15Days

- 100,000 tons/year

Product introduction

Graphite electrode is a kind of high-temperature resistant graphite conductive material produced by a series of processes such as kneading, molding, baking, impregnation, graphitization and mechanical processing, using petroleum coke and needle coke as aggregates and coal tar pitch as binder. It has good stability, corrosion resistance, thermal conductivity and low penetration point.

China UHP Graphite Electrodes

Graphite electrode, mainly petroleum coke, needle coke as raw material, coal pitch as binder, calcination, ingredients, kneading,molding, baking and graphitization, machining and made, which is released in electric arc furnace in the form of arc conductor of electricity to heat melting furnace charge, with low resistivity, good conductivity, low ash, uniform and compact structure, good oxidation resistance, high mechanical strength, etc.

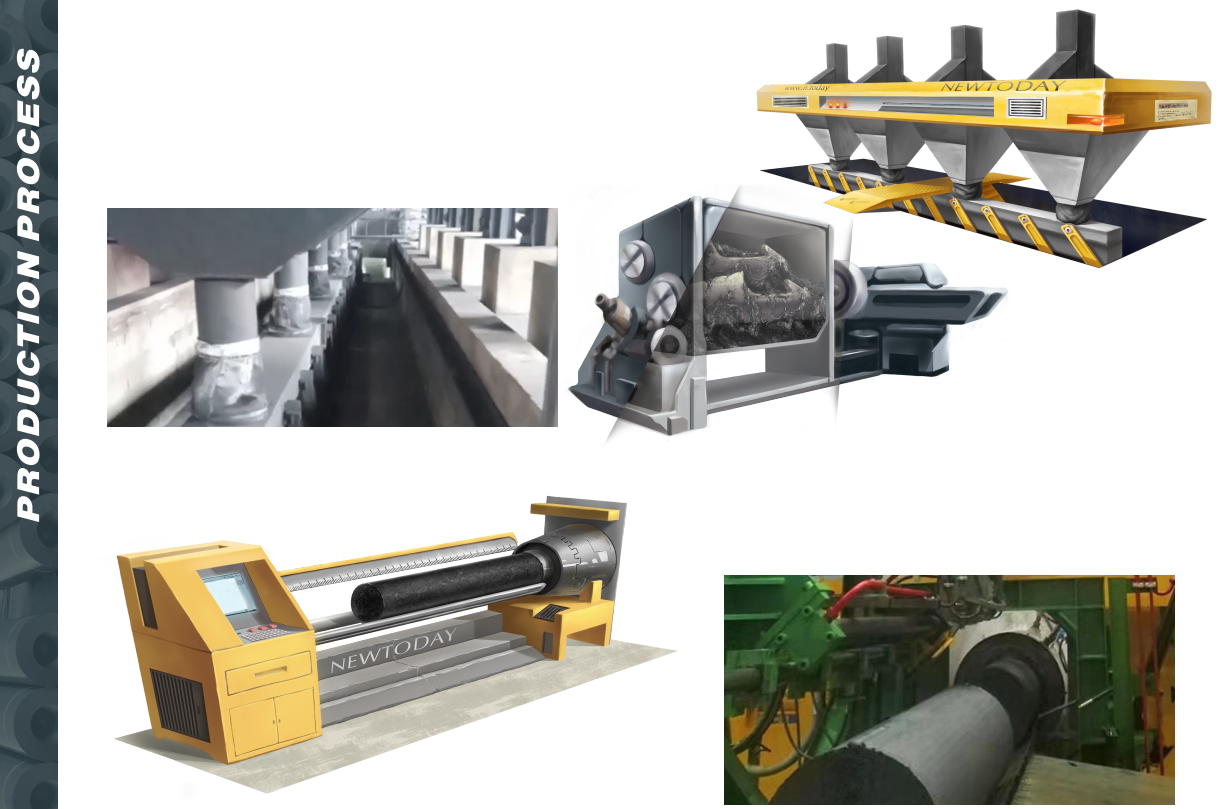

1、High quality needle coke or petroleum coke is broken into particle size meeting process requirements by mechanical equipment after self calcination.

2、CRUSHING SCRECNING BURDENINGKNEADING

Needle coke is broken in mechanical equipment, and after screening, it isproportioned according to the proportion required by the formula. Thescreened raw material particles are mixed with a certain proportion ofasphalt according to the formula requirements, and heated and stirred toform a paste with certain plasticity.

3、FORMING

The paste with a suitable temperature is added to the molding machine, pressed and extruded, and formed into a green body according to the specification.

4、BAKING FOR THE FIRST TIME

The graphite electrode is roasted to a certain temperature in the roasting furnace according to the process requirements.

5、IMPREGNATION

The roasted graphite electrode is treated with special asphalt under vacuum and high pressure to make the product more compact.

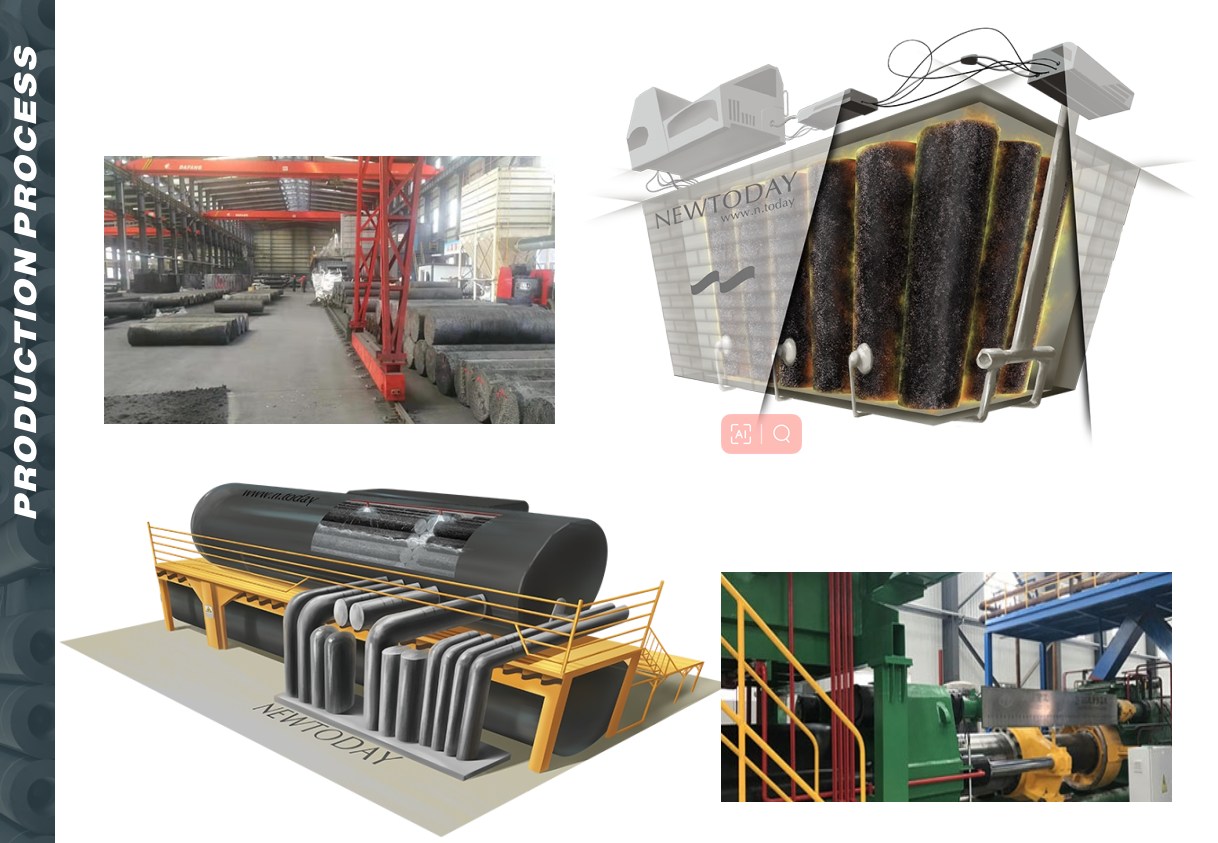

6、BAKING FOR THE SECOND TIME

After the impregnation, the products are fired in the tunnel kiln for the second time to fully coke the asphalt and improve the density and strengthof the products.

7、GRAPHITIZATION

After calcination, the product is heated to above 3000 °C in the graphitization resistance furnace so that the carbon atom structure can be rearranged into a specific graphite crystal form.

8、MACHINING

The graphitized products are machined into finished products that meet the dimensional accuracy requirements.

Application Of Graphite electrodes:

Graphite electrodes are used mainly in ladle furnaces,electric-arc furnace steelmaking,Yellow phosphorus furnace , Industrial silicon furnace or melting copper. They are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in this demanding environment.High Quality Needle Coke in HP&UHP graphite electrode,ensure the electrode application is perfect. Graphite electrodes are also used to refine steel in ladle furnaces and in other smelting processes.

Characteristics Of Graphite electrodes:

Our graphite electrodes are with low electric resistance, high density, high anti-oxidation capability, precise machining accuracy, especially with low sulphur and low ash will not give steel second time

1. Low electric resistance

2. High density

3. Good electrical conductivity

4. High anti-oxidation capability

5. Precise machining accuracy

6. Low sulphur and low ash, not give steel second time impurity

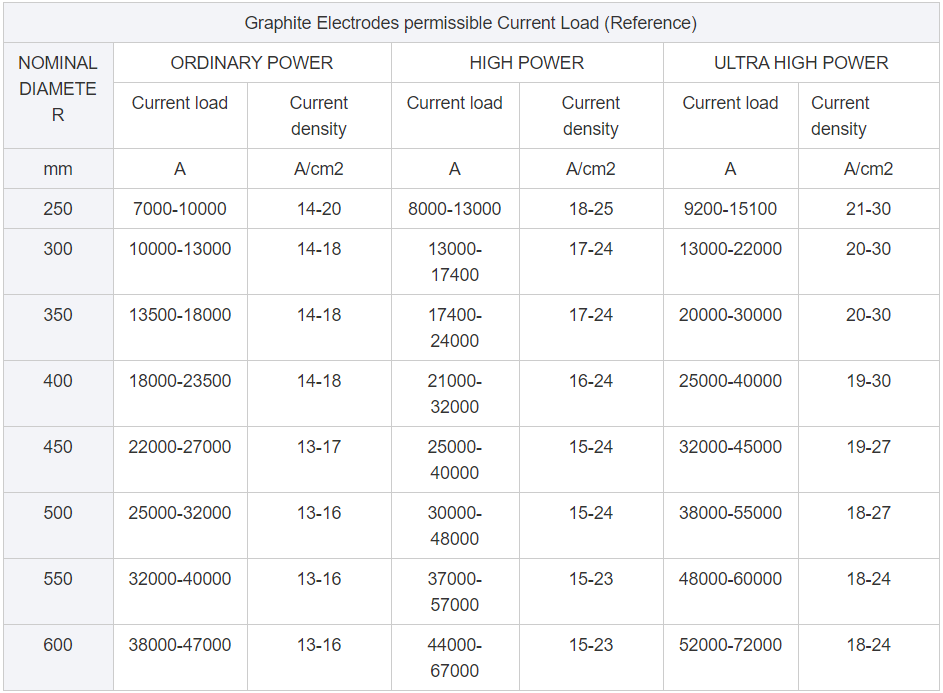

Product Paramenters