NEWTODAY: A Rising Star in the Graphite Electrode Field

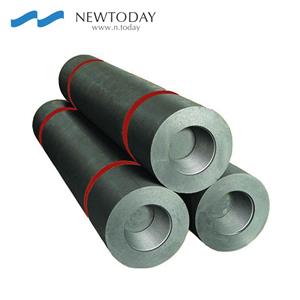

In the ever-evolving and highly competitive electgraphite rode industry, NEWTODAY has truly emerged as a formidable and remarkable new force. This dynamic company has made a significant impact on the market with its meticulously crafted ultra-high-power graphite electrodes.

The production process of these electrodes is a testament to NEWTODAY's commitment to excellence. It begins with the painstakingly careful selection of raw materials. The company scours the market for only the highest quality graphite and binders. Each raw material is thoroughly inspected and tested to ensure it meets the strictest quality standards. This attention to detail in the selection process is crucial as it forms the foundation for the superior quality of the final product. Once the raw materials are selected, advanced processing technologies come into play. NEWTODAY invests heavily in state-of-the-art equipment and technologies to ensure that every step of the production process is optimized. From the mixing and molding stages to the baking and graphitization processes, precision and expertise are evident. The application of these advanced technologies not only enhances the efficiency of production but also guarantees the consistency and quality of the graphite electrodes. As a result of this meticulous approach, each and every graphite electrode produced by NEWTODAY has exceptional excellent quality. These electrodes are designed to perform in the most demanding environments. In application fields such as electric arc furnace steelmaking, they truly shine. Electric arc furnace steelmaking is a complex and intense process that requires electrodes that can withstand high-intensity current. The graphite electrodes from NEWTODAY are up to the task. They can firmly withstand the punishing currents and maintain their structural integrity. In addition to their ability to withstand high-intensity current, these electrodes also possess excellent electrical conductivity. This property is essential for efficient energy transfer in the steelmaking process. The high electrical conductivity of NEWTODAY's graphite electrodes ensures that the electrical energy is effectively utilized, reducing energy waste and increasing productivity. Moreover, these electrodes have remarkable thermal stability. They can endure the extreme temperatures generated in the electric arc furnace without deteriorating or losing their effectiveness. NEWTODAY is not content with resting on its laurels. The company is constantly and continuously innovating in the extensive field of graphite electrodes. Its team of dedicated researchers and engineers are always on the lookout for new formulations and structures that can further enhance the performance and application range of graphite electrodes. By investing in research and development, NEWTODAY is able to stay ahead of the curve and meet the evolving needs of its customers. For example, through extensive research and experimentation, the company has developed new formulations that improve the strength and durability of the electrodes. These new formulations also enhance the electrical conductivity and thermal stability, making the electrodes even more suitable for demanding applications. In addition to new formulations, NEWTODAY is also exploring innovative structures for graphite electrodes. These new structures can offer improved heat dissipation, increased resistance to wear and tear, and better electrical performance. By researching and energetically developing these new formulations and unique structures, NEWTODAY has further expanded the extensive application range of graphite electrodes. These electrodes are now being used in a variety of industries beyond steelmaking, such as in the production of non-ferrous metals, silicon carbide, and other high-temperature applications. This expansion of the application range provides customers with a greater variety of choices and opens up new opportunities for growth and development. In conclusion, NEWTODAY's emergence as a new force in the graphite electrode industry is a testament to its commitment to quality, innovation, and customer satisfaction. With its meticulously produced ultra-high-power graphite electrodes, continuous improvement of production processes, and unwavering dedication to innovation, the company is well-positioned to lead the way in the development of the graphite electrode industry. As the industry continues to evolve, NEWTODAY will undoubtedly play a crucial role in shaping its future.