Graphite Electrodes: A Key Player In The Shift Toward Sustainable Steelmaking

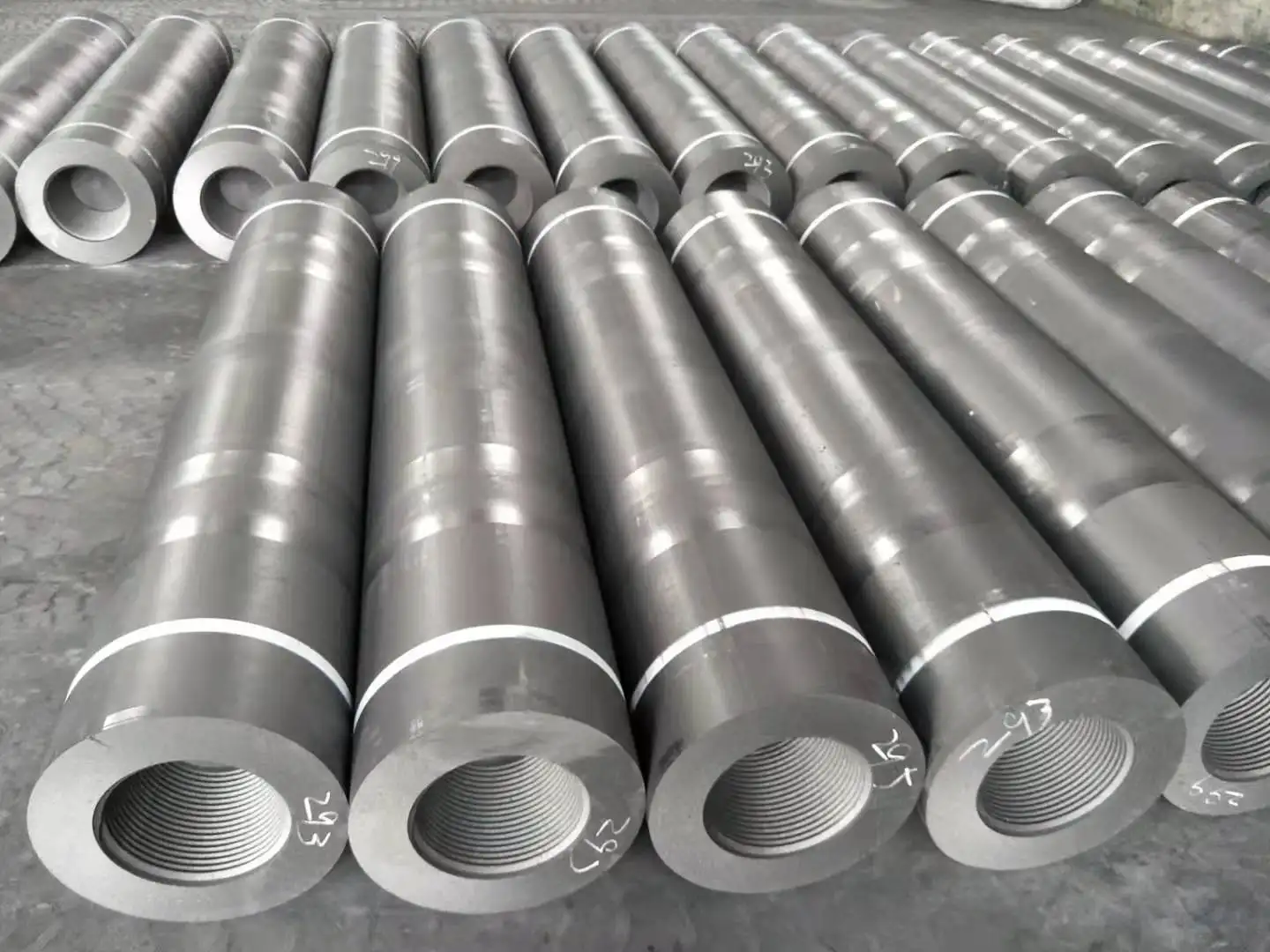

In today's rapidly evolving industrial landscape, as industries spanning the entire globe place an ever-increasing emphasis on sustainability, the demand for graphite electrodes in electric arc furnace (EAF) steelmaking has witnessed a remarkable upsurge. This surge is not merely a coincidence but a reflection of the crucial role that graphite electrodes play in the pursuit of green steelmaking.Graphite electrodes stand at the very core of the green steelmaking process. In this paradigm, the overarching focus is firmly centered on minimizing emissions and curbing energy consumption. The incorporation of graphite electrodes in EAF steelmaking paves the way for a more sustainable production methodology. These electrodes act as the linchpin, enabling a series of processes that contribute to a greener approach to steel production. One of the key advantages of using graphite electrodes in EAF steelmaking is their ability to facilitate a reduction in overall energy consumption. This is achieved through their efficient electrical conductivity and thermal stability. By optimizing the energy transfer during the steelmaking process, graphite electrodes help industries cut down on unnecessary energy wastage. This not only leads to cost savings but also aligns with the global drive towards sustainable practices. Moreover, graphite electrodes play a vital role in reducing emissions. Their use in EAF steelmaking helps to minimize the release of harmful pollutants and greenhouse gases. This is particularly significant in an era where environmental concerns are at the forefront. Industries are under increasing pressure to adopt cleaner production methods, and graphite electrodes offer a viable solution to meet these demands. The importance of graphite electrodes in green steelmaking cannot be overstated. They provide industries with a means to achieve their sustainability goals while simultaneously enhancing their production efficiency. As the world continues to grapple with the challenges of climate change and resource depletion, the role of graphite electrodes in EAF steelmaking becomes even more crucial. Industries that embrace the use of graphite electrodes are not only making a positive impact on the environment but also positioning themselves for long-term success. By adopting a more sustainable production approach, they are able to meet the evolving expectations of consumers, regulators, and society as a whole. In conclusion, as the global push for sustainability intensifies, the demand for graphite electrodes in EAF steelmaking is set to continue its upward trajectory. These electrodes are not just a component of the steelmaking process but a catalyst for change, driving the industry towards a more sustainable future.