-

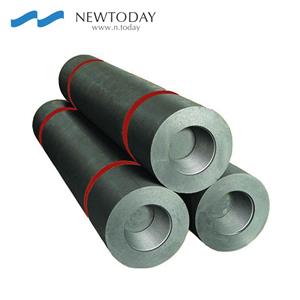

NEWTODAY Sets New Standards in Graphite Electrode Quality and Sustainability

NEWTODAY has introduced a series of improvements in its graphite electrode manufacturing, focusing on quality and sustainability. These upgrades address the steel industry’s growing need for energy-efficient and environmentally friendly production solutions, positioning NEWTODAY at the forefront of eco-friendly graphite electrode innovation.

05-11-2024 -

NEWTODAY Expands Graphite Electrode Production to Support Global Steel Industry Growth

NEWTODAY has announced a major expansion in its production capacity for graphite electrodes to meet increasing demand from the steel manufacturing sector. This initiative supports the shift towards eco-friendly Electric Arc Furnace (EAF) technology, where UHP graphite electrodes are essential for optimizing efficiency and reducing environmental impact.

31-10-2024 -

Graphite Electrode Market Shifts as Steel Producers Pursue Cleaner Technologies

The graphite electrode market is undergoing significant changes, driven by global steel manufacturers adopting eco-friendly production methods, including Electric Arc Furnace (EAF) technology. This transformation highlights the role of Ultra High Power (UHP) graphite electrodes in achieving higher energy efficiency and reducing carbon emissions.

29-10-2024 -

NEWTODAY Boosts Production Capacity to Meet Growing Demand for Graphite Electrodes

NEWTODAY is expanding its production capabilities to keep pace with the rising demand for high-quality graphite electrodes, especially in the steel manufacturing industry. The company’s focus on Ultra High Power (UHP) technology aims to increase efficiency and support sustainable production practices, meeting the global market's evolving needs.

25-10-2024