Graphite Electrode Market Shifts as Steel Producers Pursue Cleaner Technologies

Graphite Electrode Market Shifts as Steel Producers Pursue Cleaner Technologies

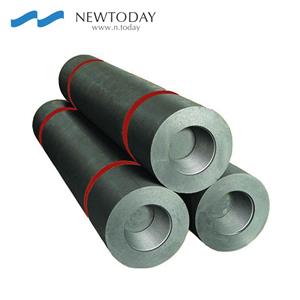

In response to global calls for more sustainable industrial practices, the graphite electrode market is adapting to support the steel industry’s transition towards cleaner and more energy-efficient methods. With many steel producers moving from traditional blast furnaces to Electric Arc Furnace (EAF) technology, the demand for Ultra High Power (UHP) graphite electrodes has seen a notable increase. UHP electrodes are vital for EAF applications, as they enable the high-temperature operations necessary for efficient steel production while also helping reduce overall carbon emissions.

This industry shift is particularly evident in regions where environmental regulations are tightening, prompting steel manufacturers to adopt technologies that contribute to carbon emission reduction. The demand for high-quality graphite electrodes has consequently surged, especially in countries committed to sustainable development goals. Graphite electrode manufacturers are responding by investing in advanced production techniques to deliver durable, high-performance electrodes that meet the steel sector's needs for both efficiency and sustainability.

The transition to more eco-friendly steel production methods signals a promising future for the graphite electrode industry, with innovations aimed at suppor ting long-term energy efficiency. As these trends continue, the role of graphite electrodes in facilitating cleaner steel manufacturing will likely remain central to the industry’s ongoing evolution.