New Opportunities in the Graphite Electrode Market

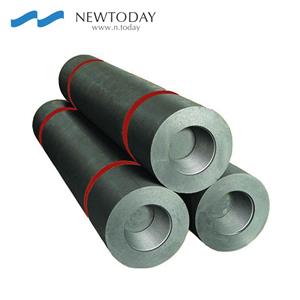

As the relentless march of global manufacturing continues unabated, the demand for graphite electrodes, which serve as an indispensable consumable in electric arc furnace steelmaking and a plethora of other industrial processes, is experiencing a swift and significant increase. This escalating demand is a testament to the crucial role that graphite electrodes play in the complex tapestry of modern industrial production.Graphite electrodes are renowned for their exceptional combination of high conductivity, remarkable heat resistance, and stable chemical properties. These characteristics endow them with a unique and essential status in a wide range of applications. In steel smelting, for instance, they are the linchpin that enables the intense heat and electrical energy required for the transformation of raw materials into high-quality steel. The high conductivity of graphite electrodes ensures efficient transfer of electrical current, facilitating the melting and refining processes. At the same time, their heat resistance allows them to withstand the extreme temperatures generated in the steelmaking furnace without deteriorating or losing their effectiveness.

In silicon production, graphite electrodes also play a vital role. The production of silicon demands extremely high temperatures, and graphite electrodes are well-suited to meet this challenge. Their stable chemical properties ensure that they do not react with the silicon or other substances involved in the production process, maintaining the purity and quality of the final product.

Beyond steel smelting and silicon production, graphite electrodes find extensive use in other high-temperature applications. In industries such as non-ferrous metal smelting, chemical processing, and glass manufacturing, they are essential for achieving the high temperatures necessary for various processes. Their ability to withstand extreme heat and maintain their structural integrity makes them a reliable choice for these demanding applications.

As global manufacturing continues to evolve and expand, the demand for graphite electrodes is likely to remain strong. Their unique properties and essential role in various industrial processes make them an integral part of the modern industrial landscape. With ongoing research and development efforts aimed at improving their performance and reducing costs, graphite electrodes are poised to play an even more significant role in the future of global manufacturing.

Our company is dedicated to providing high-quality graphite electrode products to meet diverse industrial needs. We strictly control our production processes to ensure that each graphite electrode performs reliably under high-temperature and high-pressure conditions.

In the face of market challenges and opportunities, we will continue to optimize our products and enhance our services to better support our customers. Moving forward, we will focus on technological innovation and environmental sustainability, contributing to the long-term development of global industries.